PROCESS

In-house design & build

The Process.

The company has adopted an agile design methodology and works in tandem with our customers to make sure the optimal end product is delivered.

This methodology uses the following stages:

Method 1

2D drawings and console design requirement gathering from client

Clients will specify console type and specifications required

Method 2

Floor plan and specification gathering from client

CTF will propose a project-specific solution that fits the requirements

.webp?width=2000&name=Room%20Render%20E%20Class%2003%20(1).webp)

.webp?width=2000&name=Room%20Render%20E%20Class%2001%20%20(1).webp)

-1.webp?width=2000&name=K%20Class%20Room%2002%20%20(3)-1.webp)

-1.webp?width=2000&name=K%20Class%20Room%2001%20(1)-1.webp)

.webp?width=2000&name=Room%20Render%20E%20Class%2001%20(2).webp)

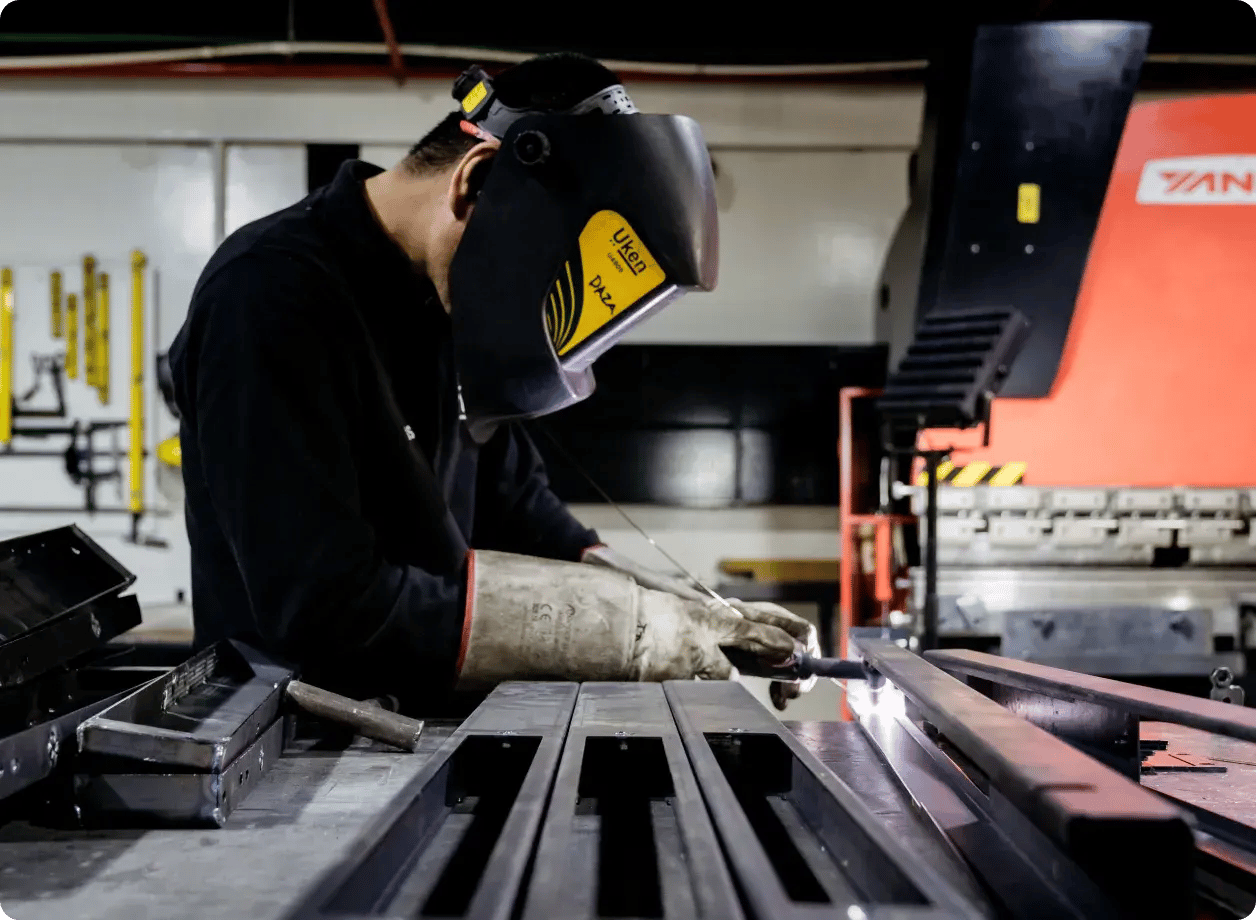

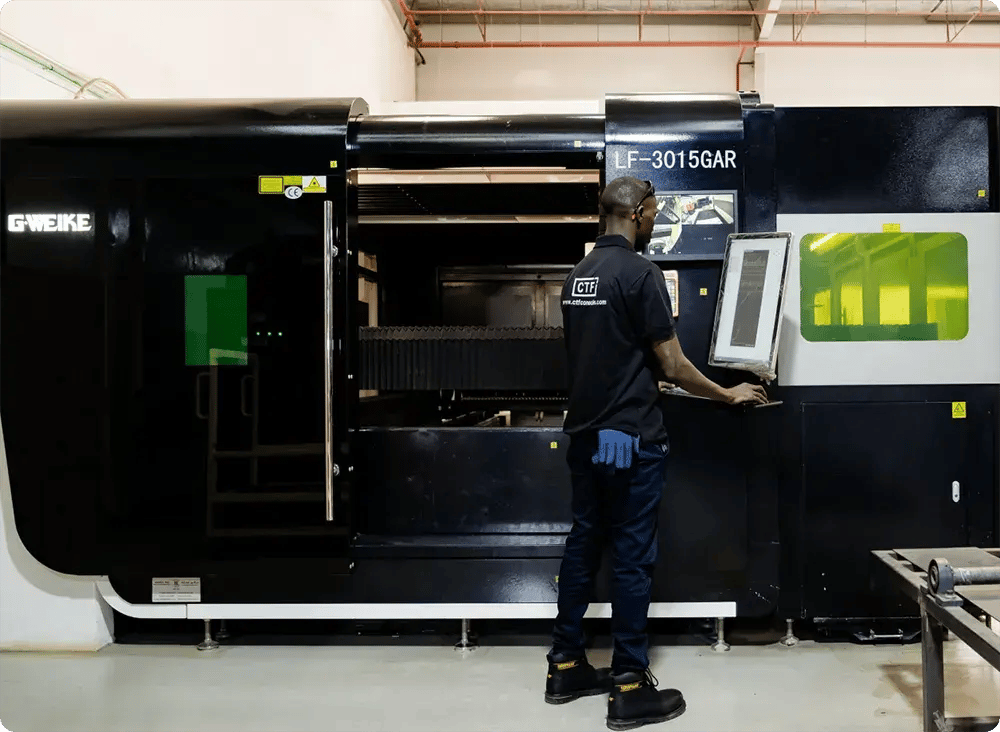

Quality Control.

At CTF we ensure that our consoles are manufactured to the highest quality standards by following a rigorous quality check and control process in line with ISO 9001-2015 certification requirements.

Quality checks are performed at each of the different stages of the production process detailed below to enhance product reliability, performance, and customer satisfaction.

Design and engineering

Raw Material Inspection

Factory Acceptance Test

Finishing and Aesthetics

Product assembly

Compliance and Safety Training

Documentation and Packaging

Delivery and Installation

Laser Cutting Inspection

Bending Inspection

Site Acceptance Test

Product Design Features.

Common control room challenges

Control room consoles are critical components of control rooms and they can either help or hinder the operators to do their mission critical work. Commonly faced challenges include:

- Ergonomics and adjustability

- Cable management and accessibility

- Heat management

- Flexibility and scalability

- Integration of technology

- Aesthetics and branding

At CTF, we are constantly innovating our console designs working closely with consultants and operators to design ergonomic, functional and efficient control room console solutions that meet and exceed the ISO 11064-4 standards.

Cable management

Effective cable management is very important for control room consoles to facilitate maintenance, ensure optimal performance and remove trip hazards. CTF recognizes the issues that can arise from poor cable management and designs its consoles with the most efficient cable routing systems, equipped with optional surge protection, separate power and data cables for noise free data transfer and protection from data leaks and data tapping.

- Cable trays

- Cable raceways

- Cable clip and ties

- Convenient access points for maintenance

- Surge protection

.webp?width=2000&height=2000&name=3d-01%20(6).webp)

Heat management

CTF’s consoles are well provisioned with ventilation slots within the internal equipment compartment panels for a more homogenous natural ventilation effect, supported by state-of-the-art quiet fans for efficient cooling. Our console design ensures that no air gets blown on the operator to ensure maximum operator comfort and efficiency.

.webp?width=2000&height=2000&name=3d-01%20(4).webp)

Antibacterial surfaces

CTF's consoles feature an antibacterial surface designed to provide continuous protection throughout multiple shifts. This specialized surface enhances hygiene and promotes a healthier environment, ensuring maximum productivity, especially in 24-hour operations.

Height Adjustment

CTF’s sit/stand consoles allow operators to customize their workstation to suit individual height preferences and ergonomic needs, supporting various health benefits.

- Increased operator comfort

- Improved posture by reducing body and neck strain

- Higher calorie burn

- Improves mood and focus for increased productivity

- Better blood circulation

CTF’s sit/stand consoles come with the following features:

- Electrically powered height adjustment

- Multiple Height Options

- Adjustable up to 1.2 m

- Ability to preset height preferences

- Can be controlled by CTF’s C Control™ iPad based management platform.

.webp?width=2000&height=2000&name=3d-01%20(7).webp)

Meet with CTF Consoles

Whether it's to discuss your next project or learn more about our products, arrange a meeting with the CTF Consoles team and let's start a conversation.

ACCREDITATIONS

Contact The CTF Team

Start a conversation with the CTF Consoles team to discuss your technical furniture requirements or make a new sales enquiry.